Attention

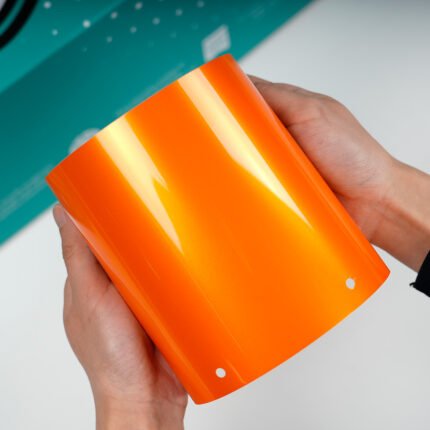

“WET & DRY APPLIED COLOR PPF “

our car is an extension and symbol of you. Do not let daily dangers turn your pride and joy into a mass of scars and fragments. Protect it with our Color Paint Protective Film (color PPF), which is an unparalleled armor. It prevents debris, scratches and fading, giving you the best protection. Order now and keep your car flawless.

TPU Color paint protective film protects your car from damage caused by stone debris, scratches, splashes and any minor wear, preventing paint fading and extending its service life. At the same time, it is different from the conventional transparent car paint protection, TPU Color PPF we provide a variety of colors for you to choose, while protecting the car paint, you can choose any color you like.

TPU Matte Color PPF Series is a kind of high performance aliphatic thermoplastic polyurethane film (TPU). Using TPU substrate as the carrier, the liquid TPU color layer is uniformly attached to the surface of the substrate through ultra-precision coating technology to form a high saturation and high gloss color film . It can prevent the damage caused by stone chips, scratches, etc., and the PET Liner is used as the backing of the glue, which can be WET & DRY APPLIED to make the construction more efficient.

TPU Gloss Color PPF Series, due to the need to maintain the brightness of the surface only WET application backing, if the customer needs WET & DRY APPLIED, 5 roll can be customized.

1. Performance Properties

| Product thickness (Total) | 337 um |

| Application layer thickness | 212 um |

| Peel Adhesion (Tack) | ≈ 1200 g/inch |

| Tendile Strength | ≥ 30 Mpa |

| Maximum Temperature | 100 ℃ |

| Elongation at Break (Coat) | 140 ℃ |

| Elongation at Break (Product) | 372% |

| UV Resistance | ≥ 95% |

| Light Transmission | 90% |

| Size | 1.52m x 15m |

| Coating type | Hydrophilic |

Warranty: 5years from production date. The product is warranted to be free of defects in the material. In case of product defects communicated in the mentioned period, BeforeAfter will consider and determine the existence of the defect and further decide at its sole discretion to either replace the defective product without charge or compensate it with money in such amount, as BeforeAfter deems reasonable.

* UVA bulb is used in QUV, with 50°C UV exposure and 4 hours of 60°C condensations.

2. Properties of Coating Material

The base material A is a curing PU solvent developed with thermal remediation technologies (TRT), showing excellent performance and is highly stain resistant. Signs marked with a marker pen can be easily wiped away.

Usage: Including but not limited to vehicle wrap and phone case protection film.

Top coating features: solvent and stain resistance, resistance to heavy metals, resistance to scratches, self-healing (TORAY)

Application: Thermoplastic polyurethanes.

TRT is activated to avoid tearing when slight damages caused by external forces occur. Highly durable with a flexible and stretchable structure.

3. Properties of Adhesive

Adhesive A is a pressure-sensitive polymer made of sone-part structural self-curing adhesive and acrylate, which will start curing at a proper temperature when the solvent volatilizes completely. It takes a week for it to become complete curing at room temperature. Adhesive A has superior cohesion with a plasticizer-resistant characteristic and excellent chemical properties, perfect for base materials like PVC or TPU.

Suitable Application

- Sign

- Decal and label

- Composite film

- Car paint protection film

Characteristics

- Self-curing

- One-part structural

- Safe for direct application to coating

- Superior cohesion

- Plasticizer resistance

- Repositionable technology

- Soluble in ketone, ester, arene, and aliphatic.

- Contact us

·Whatsapp: +86 15814692927

·Ins:vinylwrap_beforeafter

Reviews

There are no reviews yet.